Maître charron.

Wheelwright.

Jacques was a Maître charron. As a master he oversaw workers and may have had apprentices who sought to learn the trade from him.

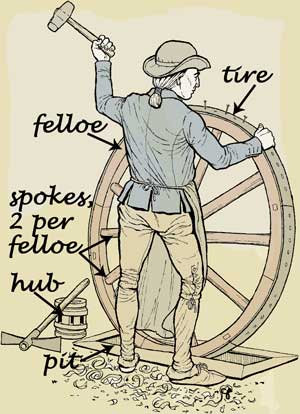

The wheelwright made and repaired wheels for wagons, carts, carriages and coaches. He needed to understand the properties of various types of wood as well as the level of stress placed on the different parts of the wheel. Elm was best for the nave or hub, for spokes he chose seasoned oak, and the curved portion of the wheel, the felloes, were often of beech.

In constructing the wood wheel, craftsmen started at the hub or nave. The bark was left on the cylindrical piece of wood that had been augered (bored) and cut to a length of about 16 inches. Left to season for anywhere from 2 to 8 years, it was then turned on a lathe to form, and then mortises (slots) were cut to receive the spokes. Felloes, the curved sections, attached to two spokes each and joined together.

He worked with a blacksmith who shaped the iron strake or hoop which served as a tire trimming the wheel. The circumference of the wheel was measured using a traveler. Once the hot iron tire was formed it was nailed to the wheel and rapidly cooled. As it contracted it tightly secured all the wood parts.

In Jacques' multitude of contracts it appears he also used his carpentry skills to build and repair other wooden structures.

- A Museum of Early American Tools, Eric Sloane, Funk & Wagnalls, New York: 1964, pp 96-97

- Dictionnaire National…, p 1247

- Old Occupations: Wheelwrights', by Mary Carter - Family Tree Magazine October 1992